Industrial Inspections

you are here: IRT home > Thermal Imaging > Industrial Inspections

Infrared inspections are one of the best proven and cost effective ways of protecting a companies assets. Infrared inspections can be a valued part of any predictive maintenance programme and many larger companies have developed regular predictive maintenance programmes that include infrared inspections.

This proactive approach to maintaining a company's assets is an easy choice. Reactive unplanned downtime is costly and can spell disaster for companies who are already running on lean budgets. Infrared inspections can help reduce costly downtime and help create a safer working environment, thereby preventing possible injury to valued personnel. The exact return on investment varies with each infrared programme but a minimum of 4-1 can be expected.

Infrared inspections can also help minimize a companies potential for losses. Many insurance companies are aware of the benefits of infrared inspections and now insist on these inspections in order to renew existing policies, with some offering lower premiums for those that have periodic inspections.

The following inspections can be undertaken by IRT Consult, UK:

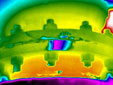

- Monitoring vessel levels

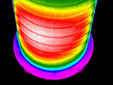

- Insulation integrity inspections on petrochemical process lines

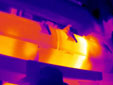

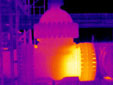

- Process equipment condition monitoring and predictive maintenance

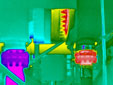

- Identifying blockages and malfunctions in petrochemical process lines

- Mechanical equipment inspections

- Site electrical inspections

- Separating Drum

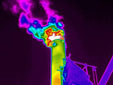

- Gas Flares

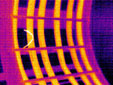

- Induction Coils

- Hopper Linings

- Pipeline Casings

- Solder Bath

- Tank Levels

- Valve Operation

- Cable Protection

- Drive Gear

- Flange Seals

- Rendering Plants

Contact IRT Consult, UK now to arrange a thermographic survey.