Mechanical Inspections

you are here: IRT home > Thermal Imaging > Mechanical Inspections

It’s not only electrical parts which can fail during production, mechanical items such as pumps, gears, clutches, bearings, belts, heat exchangers, pressure accumulators, conveyors etc all have a tendency to fail, often during production costing 000’s in lost production, orders and wages not to mention the often costly repair or replacement of the failed component itself.

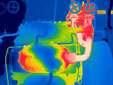

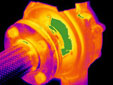

In this modern world of maximizing machine running time coupled with often irregular or poor maintenance schedules, we can see lack of lubrication servicing, causing worn-out machine parts which in turn create more friction and added friction causes the damaged component to have a higher temperature than an intact component.

Regularly surveying rotating equipment will allow you to carry out trending (Monitoring) of it’s condition and even to predict failure.

- Shaft Bearings

- Shaft Bearings

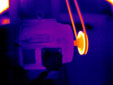

- Conveyor Drive

- Induction Coils

- Cooling Jackets

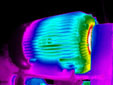

- Drive Motors

- Drive Pulleys

- Centrifugal Pump

With a Mechanical Thermographic Survey from IRT Consult, UK damaged or failing components can be identified before they fail and thus can be changed in time, before costly breakage or interruption occurs.

The Benefits of a Thermographic Survey

We work with our clients to increase equipment reliability, decrease downtime and we can even help increase production output from certain types of equipment.

If your facility cannot afford the expense of production equipment breaking down, then the cost conscious maintenance/facilities manager should schedule a Thermographic Survey without delay.

For every £ spent on a survey will reap multiples in return by ensuring your facility is up in production without any costly downtime.

Contact IRT Consult, UK now to arrange a thermographic survey.